我们已经为您编辑了一些计算程序。可以为液体和气体计算kv值,流量和压差。在计算气体工况时,低于临界(P2 > P 1/2)和高于临界(P2 < P1/2)有一个额外的区别。

所有计算都是经验公式,也就是简化了各个案例,所以只能用于指定的工况。

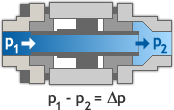

为了计算流量Q,必须提供kv值、介质的阀前密度ρ1和阀门的压差(Δp)。

为了计算压差(Δp),必须提供kv值、介质的阀门密度ρ1和流量Q。

为了计算kv值,必须提供在1013 hPa 和 0°C时的体积流量QN、介质的标准密度ρN、阀门上的压差(Δp)、阀门下游压力P2和入口介质温度。

为了计算流量QN,必须提供kv值、介质的标准密度ρN、阀门上的压差(Δp)、阀门下游压力P2和入口介质温度。

为了计算压差,必须提供kv值、在1013 hPa 和 0°C时的体积流量QN、介质的标准密度ρN、阀门下游压力P2和入口介质温度。

| DN in mm |

Flow Velocity | |||||||||

| 0,5 m/s |

1,0 m/s |

1,5 m/s |

2,0 m/s |

3,0 m/s |

4,0 m/s |

5,0 m/s |

7,0 m/s |

8,0 m/s |

10,0 m/s |

|

| 8 | 1.5 | 3.0 | 4.5 | 6.0 | 9.0 | 12.1 | 15.1 | 21.1 | 24.1 | 30.2 |

| 10 | 2.4 | 4.7 | 7.1 | 9.4 | 14.1 | 18.8 | 23.6 | 33.0 | 37.7 | 47.1 |

| 12 | 3.4 | 6.8 | 10.2 | 13.6 | 20.4 | 27.1 | 33.9 | 47.5 | 54.3 | 67.9 |

| 15 | 5.3 | 10.6 | 15.9 | 21.2 | 31.8 | 42.4 | 53.0 | 74.2 | 84.8 | 106.0 |

| 16 | 6.0 | 12.1 | 18.1 | 24.1 | 36.2 | 48.3 | 60.3 | 84.4 | 96.5 | 120.6 |

| 20 | 9.4 | 18.8 | 28.3 | 37.7 | 56.5 | 75.4 | 94.2 | 131.9 | 150.8 | 188.5 |

| 25 | 14.7 | 29.5 | 44.2 | 58.9 | 88.4 | 117.8 | 147.3 | 206.2 | 235.6 | 294.5 |

| 32 | 24.1 | 48.3 | 72.4 | 96.5 | 144.8 | 193.0 | 241.3 | 337.8 | 386.0 | 482.5 |

| 40 | 37.7 | 75.4 | 113.1 | 150.8 | 226.2 | 301.6 | 377.0 | 527.8 | 603.2 | 754.0 |

| 50 | 58.9 | 117.8 | 176.7 | 235.6 | 353.4 | 471.2 | 589.0 | 824.7 | 942.5 | 1178.1 |

| 65 | 99.5 | 199.1 | 298.6 | 398.2 | 597.3 | 796.4 | 995.5 | 1393.7 | 1592.8 | 1991.0 |

| 80 | 150.8 | 301.6 | 452.4 | 603.2 | 904.8 | 1206.4 | 1508.0 | 2111.2 | 2412.7 | 3015.9 |

| 100 | 235.6 | 471.2 | 706.9 | 942.5 | 1413.7 | 1885.0 | 2356.2 | 3298.7 | 3769.9 | 4712.4 |

| 125 | 368.2 | 736.3 | 1104.5 | 1472.6 | 2208.9 | 2945.2 | 3681.6 | 5154.2 | 5890.5 | 7363.1 |

| 150 | 530.1 | 1060.3 | 1590.4 | 2120.6 | 3180.9 | 4241.2 | 5301.4 | 7422.0 | 8482.3 | 10602.9 |

| 200 | 942.5 | 1885.0 | 2827.4 | 3769.9 | 5654.9 | 7539.8 | 9424.8 | 13194.7 | 15079.6 | 18849.6 |

| 250 | 1472.6 | 2945.2 | 4417.9 | 5890.5 | 8835.7 | 11781.0 | 14726.2 | 20616.7 | 23561.9 | 29452.4 |

To avoid hydraulic shocks in pipelines, the flow velocities must be taken into account when designing valves for liquids.